Wireless IO-Link Device Management Application

About Client

Industry

Robotics and Automation

Location

Germany

Project Overview

In the realm of industrial automation, managing IO-Link devices efficiently is paramount for ensuring smooth operations. However, traditional methods often involve managing multiple sensors and reading data parameters from those sensors through cumbersome setups, requiring technicians to carry multiple laptops and cables to various industry sites. This not only complicates the process but also consumes valuable time and resources.

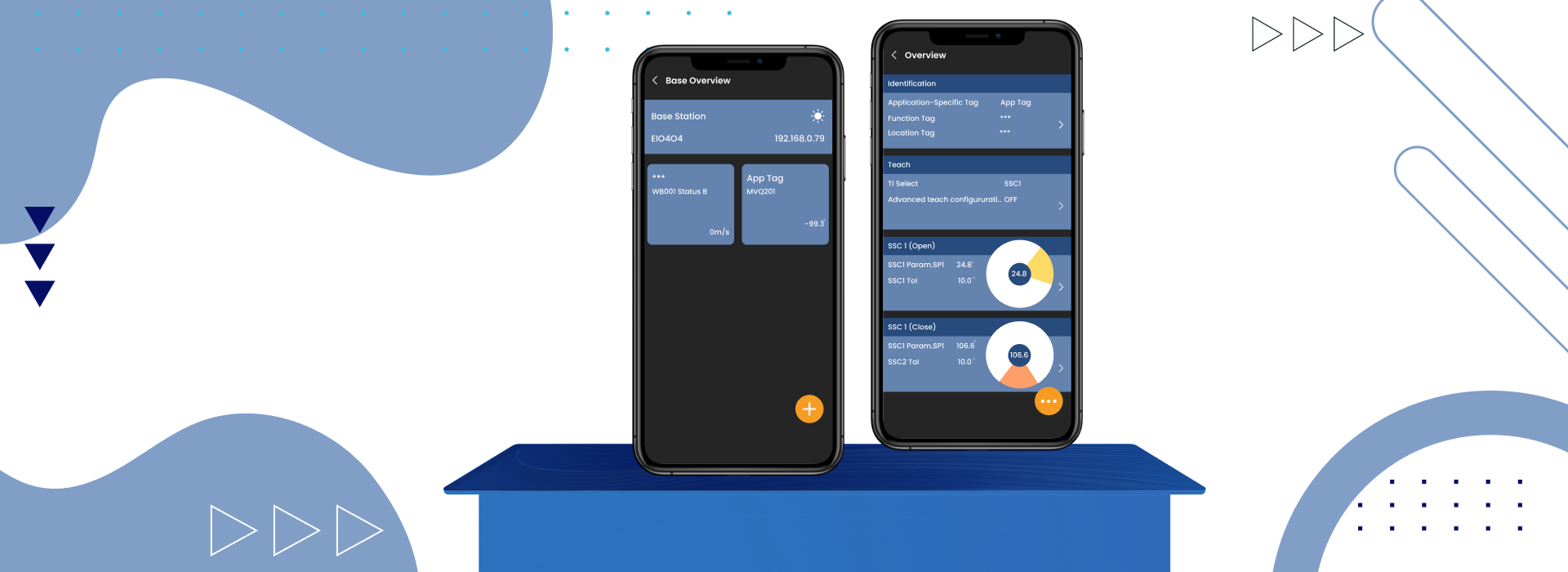

Recognizing this challenge, our team developed a groundbreaking solution: Wireless IO-Link Device Management Application – a user-friendly mobile application designed to simplify the management of IOLink devices. By leveraging Bluetooth connectivity, we aimed to provide users with a seamless way to access and update device parameters directly from their smartphones or tablets.

The core objective of our solution was to eliminate the need for bulky equipment and streamline the device management process. Through an intuitive interface, users can effortlessly connect to IOLink devices, view critical data, and make necessary adjustments with minimal effort. This not only enhances operational efficiency but also empowers technicians to perform tasks on-the-go, regardless of their location.

Traditional Process

Traditional IOLink parameterization typically involves connecting each IOLink device to a laptop using specialized IOLink cables. Technicians must physically access each sensor, which may be located in different sections of an industrial facility. This process is time-consuming and labor-intensive, requiring significant manual effort.

01

Physical Connectivity: Technicians connect the IOLink device to a laptop using the appropriate IOLink cable. This typically involves locating the device, ensuring proper cable connection, and securing the connection to prevent disruptions.

02

Configuration Software: Once the device is connected, technicians utilize configuration software on the laptop to access and adjust parameter settings. This software provides a graphical interface for configuring various parameters such as measurement thresholds, sampling rates, and communication protocols.

03

Parameter Adjustment: Technicians manually input desired parameter values into the configuration software based on operational requirements. This may involve referencing technical documentation or consulting with engineering specifications to ensure accurate configuration.

04

Verification and Testing: After parameter adjustments are made, technicians typically perform verification and testing procedures to ensure that the changes are implemented correctly. This may involve observing sensor readings or conducting test runs to validate parameter settings.

05

Documentation and Record-keeping: Throughout the parameterization process, technicians may document the changes made to each device and maintain records for future reference. This documentation helps track device configurations and facilitates troubleshooting or maintenance activities.

Traditional IOLink parameterization methods are characterized by their manual nature, dependency on physical connections, and limited mobility. While effective, these methods can be time-consuming and prone to errors, especially in large-scale industrial environments with numerous IOLink devices. As a result, there is a growing demand for more streamlined and efficient solutions that leverage modern technologies such as wireless connectivity and IoT mobile applications to simplify device management processes.

Challenges Faced

Traditional IOLink parameterization, which involves connecting devices via IOLink cables to a laptop for configuration, presents several challenges:

01

Portability Limitations: Carrying a laptop and multiple IOLink cables to different sections of an industry is cumbersome and restricts mobility. Technicians may face difficulty accessing devices in remote or hard-to-reach areas, leading to inefficiencies in the parameterization process.

02

Time Consuming: The process of connecting each IOLink device to a laptop individually can be time-consuming, especially in large-scale industrial environments with numerous sensors. This manual setup and configuration process increases downtime and delays operational tasks.

03

Dependency on Physical Connections: The reliance on physical connections via IOLink cables restricts flexibility and scalability. Technicians must physically access each device, which can be challenging in complex or hazardous environments, posing safety risks.

04

Limited Real-time Monitoring: Traditional parameterization methods typically do not offer real-time monitoring capabilities. Technicians may need to disconnect devices from the laptop to verify parameter changes, disrupting workflow and potentially causing data discrepancies.

05

Compatibility Issues: Compatibility issues between different IOLink devices, laptops, and software versions can arise, leading to configuration errors or device malfunctions. This can result in additional troubleshooting efforts and potential downtime during critical operations.

06

Training Requirements: Technicians require specific training to navigate the software interface and understand the parameterization process. High turnover rates or staff shortages may pose challenges in maintaining a skilled workforce proficient in traditional IOLink parameterization methods.

Addressing these challenges requires a modernized approach to IOLink device management that leverages wireless connectivity, intuitive interfaces, and real-time monitoring capabilities to streamline parameterization processes and enhance operational efficiency.

Our Solution

In response to the challenges posed by traditional IOLink parameterization methods, we have developed a groundbreaking IoT mobile app that revolutionizes the way users interact with IOLink devices. Our solution addresses key pain points and offers unparalleled convenience, efficiency, and reliability.

01

Cable-Free Connectivity: Our IOT mobile application eliminates the need for cumbersome IOLink cables by leveraging Bluetooth technology. Users can seamlessly connect to any IOLink device within Bluetooth range, freeing them from the constraints of physical connections and enabling unparalleled mobility.

02

Graphical Data Monitoring: We understand the importance of visualizing data in a convenient and intuitive manner. Our application presents IOLink data in easy-to-understand graphical formats, empowering users to monitor device parameters with clarity and precision.

03

Rapid Parameterization: With our mobile app, reading and writing parameters into an IOLink device is no longer a time-consuming endeavor. Through a streamlined interface and optimized workflows, users can perform parameterization tasks in a matter of seconds, enhancing operational efficiency and minimizing downtime.

04

Real-Time Diagnostics: Our IOT solution offers real-time monitoring capabilities, allowing users to diagnose and troubleshoot IOLink devices with unprecedented speed and accuracy. By providing instant access to device status and performance metrics, we enable proactive maintenance and minimize the risk of unexpected downtime.

05

Zero Downtime Maintenance: The convenience of Bluetooth connectivity means that users can connect to any IOLink device within range without disrupting ongoing operations. With our mobile app, maintenance tasks can be performed swiftly and efficiently, eliminating downtime and maximizing productivity.

By embracing the power of mobile technology and wireless connectivity, our solution redefines the IOLink parameterization experience. We empower users to configure, monitor, and maintain IOLink devices with unparalleled convenience and efficiency, ushering in a new era of operational excellence and reliability in industrial automation.

Outcome

80% Increase in IOLink Device Sales

Reduced Dependency on Support Staff for Maintenance of IOLink Devices.

90% Easier to Accurately Diagnose any IOLink Device

Seamless OTA Firmware Updates

Features

Live Process Value Monitoring

Live Diagnosis Value Monitoring

Recording and Visualizing Process Values

Graphical Representation of Live Process Data

Reading of IOLink Parameters

Writing of IOLink Parameters

Cloning of IOLink Devices

Firmware Update of IOLink Devices

Multilingual Support

Provisioning of IOLink Devices

Technology Stack

Android

- Xamarin

- .Net

IOS

- Xamarin

- .Net

Third party Integration

- IOLink protocol

- Skia Sharp

Architecture

- MVVM

Design Pattern

- Creational Design Patterns ( Singleton, Builder, Abstract Factory)